FAQs about filters

General

Q

What are the characteristics of non-woven filters?

A

Depending on the combination of materials used and production methods, there are high-density products, products with front and back sides, and products with functionality. Filters are selected based on the particle size and components of the dust to be collected, and are mainly divided into coarse dust filters, medium and high efficiency filters, HEPA and ULPA filters, etc. There are also filters for salt removal and gas adsorption.

Q

What kind of performance tests do you have for air filters?

A

For measuring the performance of air filters, the mass method (prefilters), light scattering integration method (medium and high efficiency filters), and counting method (HEPA filters) can be selected according to the filtration performance level of the filter.

There are some test standards such as ASRAE52.2, EN779, and JISB9908. In addition, ISO16890 was established and each standard is being updated according to ISO.

Q

How can I get the catalogs?

A

They can be downloaded from this site.

If you have any questions, please contact the our sales group below.

- [Non-Woven Sales Group]

- TEL: (06)6346-3351

- FAX: (06)6346-3321

Q

How can I purchase your products?

A

Please contact our sales department after confirming specific details such as product name and size.

Q

The dimensions we are using are not listed in the catalog. Can you change the dimensions according to our request?

A

The catalog lists standard dimensions. We can cut the material according to your request, so please contact our sales group.

General (Export)

Q

Can you issue a certificate of origin?

A

Issuance conditions vary depending on the destination, so please contact our sales group for details.

- [Non-Woven Sales Group]

- TEL: (06)6346-3351

- FAX: (06)6346-3321

Q

Can you do packaging for export?

A

We can do it with double cartons.

Please contact our sales group for details.

- [Non-Woven Sales Group]

- TEL: (06)6346-3351

- FAX: (06)6346-3321

Filter Terms

Q

What is a coarse particle dust filter?

A

It is a filter which is designed to capture dust particles larger than 5 μm.

As it is often installed before a medium or high efficiency filter, it is called prefilter.

It is widely used in general buildings, hospitals, complex facilities, factories, etc.

Q

What are medium and high efficiency filters?

A

They are filters which are designed to capture dust particles smaller than 5 μm.

It is used in places where a high level of cleanliness is required, such as general buildings, hospitals, complex facilities, factories, etc.

Q

What is a HEPA filter?

A

The HEPA filter is an air filter that has a particle collection rate of 99.97% or more for 0.3μm particles and an initial pressure loss of 245Pa or less.

These performances are specified by the Japanese Industrial Standards (JIS).

Q

What are medium and high efficiency filters with replaceable filter media?

A

When replacing the filters, only their “filter media packs” need to be replaced, and the frame can be reused.

Waste volume and costs can be reduced by replacing the “filter media packs” only.

Q

What is a high-efficiency filter for salt damage?

A

This filter is designed to prevent corrosion by removing sea salt particles.

The water-repellent non-woven fabric prevents redispersion due to deliquescence, making this filter suitable for salt damage prevention in factories and office buildings built along the coast.

Q

What is pressure loss?

A

It indicates the amount of energy loss when a fluid passes through a device (filter). Therefore, a filter with high pressure loss also has large energy loss.

For an air filter, it acts as a resistance when air passes through it, causing a pressure difference between the upstream and downstream sides of the filter. This is called differential pressure or pressure loss (abbreviated as PL).

The more dust is collected by the filter, the more pressure loss increases. If the filter is used beyond the final pressure loss, not only the energy loss increases but also the amount of air that can be processed decreases, leading to decrease in collection efficiency. Therefore, we recommend replacing the filter based on the specified final pressure loss.

Examples

Q

How do we determine when to replace a filter?

A

As a guideline, please replace the filter when it reaches twice as much as the initial pressure loss.

If the filter is visually deteriorated or damaged, or if the pressure loss is unknown, please contact our sales group along with the information of the filter model, processing air volume, and use conditions.

Q

What should we do if we would like to install a new filter?

A

Please check the following:

(1) Do you Install only a filter for the current equipment?

(2) Do you Install a new casing and equipment with the current equipment?

(3) What level of filter performance do you need?

*Prefilter only, pre and medium efficiency filter, etc.

In addition to the above information, other detailed information is needed for checking required filters.

Therefore, please contact our sales group for details.

- [Non-Woven Sales Group]

- TEL: (06)6346-3351

- FAX: (06)6346-3321

Q

Do you have an optimal air filter for PM2.5?

A

We have air filters for PM2.5.

Uniclean PM2.5 air filtersQ

What is the cut dimension tolerance of the filter?

A

For standard small cut filters, it is -0mm to +5mm, but it varies depending on the dimensions, so please contact our sales group for details.

Q

Is there any variation in the thickness of the filter?

A

We measure and manage the thickness at the original roll terminal during production, but the thickness may become thinner depending on the storage conditions, and the center of the roll tends to become thinner due to compression, so there is variation.

The center thickness is stated in the catalog, but it does not guarantee the thickness of the filter.

Please contact our sales group for details.

Q

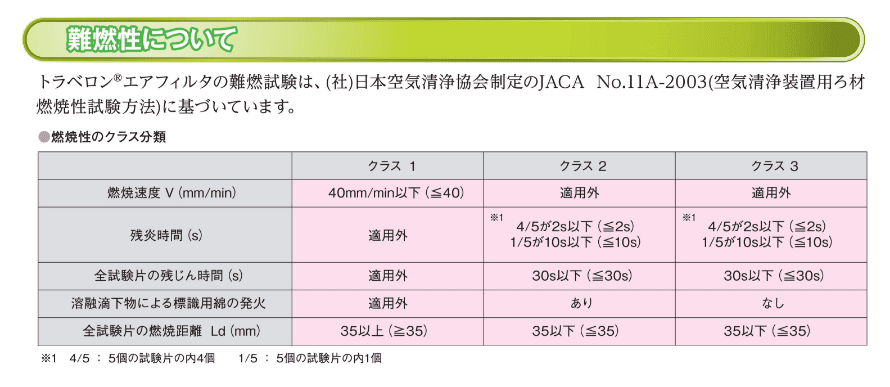

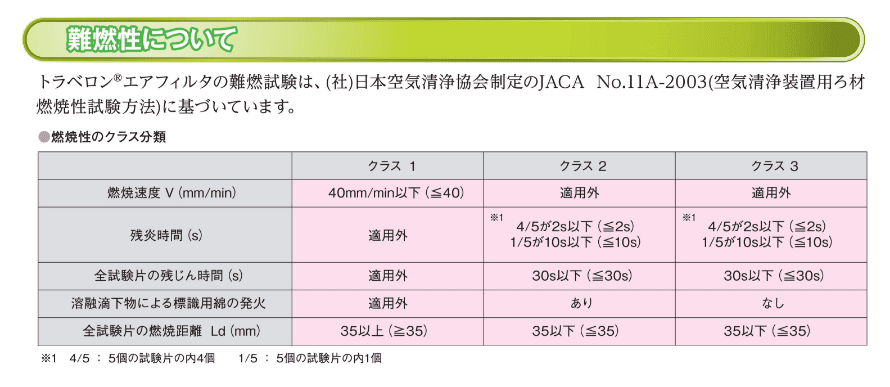

Are there any flame-retardant/non-flammable filters?

A

Our filters are not non-retardant because synthetic fibers are used for them.

We do have flame-retardant (JACA Class 3) filters.

Flame-retardant tests are conducted based on JACA No. 11A-2003 (Test method for flammability of filter media for air purifiers) established by the Japan Air Cleaning Association.

Q

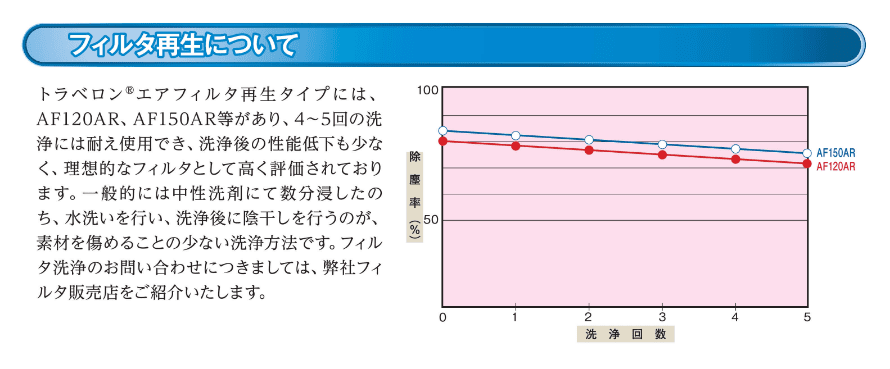

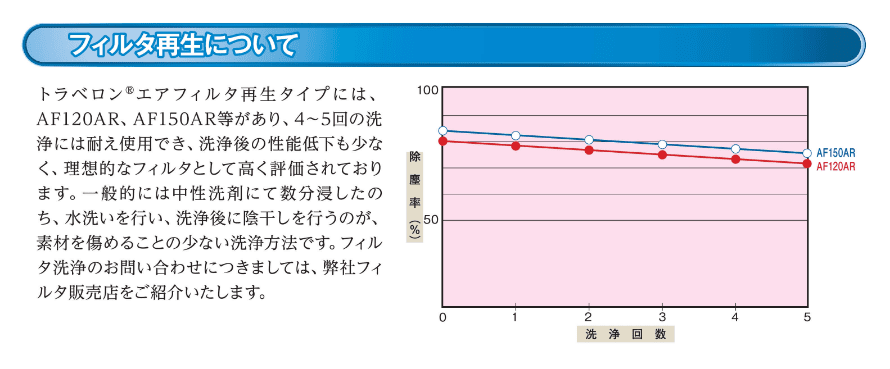

How often can the pre-filter be washed?

A

The regenerated type can withstand about 4 to 5 washes. In general, we recommend soaking in a neutral detergent, rinsing with water, and drying in the shade to minimize damage to the material.

*The number of times it can be regenerated varies depending on the use conditions and cleaning method.

CONTACT

If you have any inquiries, please feel free to contact us by telephone or email.