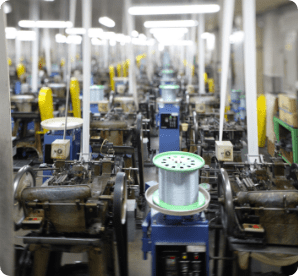

Textile Machinery Business

Our founding business, which was established in 19th century,

has continued to support the needs of the times, from clothing to smartphones.

Our founding business, which was established in 19th century,

has continued to support the needs of the times,

from clothing to smartphones.

Our founding business,

which was established in 19th century,

has continued to support the needs of the times,

from clothing to smartphones.

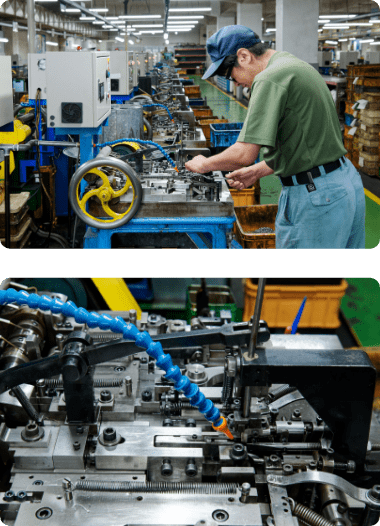

In 1984, “KANAI TRAVELLER MFG CO.” was established in Amagasaki, Hyogo Pref., and succeed in producing spinning Traveller domestically as the first company in Japan.

The Textile Machinery Division has continued to provide high-quality products not only in the textile field, but also in the manufacturing processes of non-textile fields, such as tire cords used in automobile tires, glass fibers essential to the base of smartphones and computers, and carbon fiber, which is attracting attention as a material for aircraft bodies.

The textile machinery business, which is Kanai Juyo Kogyo's founding business, has grown into a business that has been continuing to supply a large number of products with nearly 100% domestic market share, utilizing technology cultivated through more than 130 years of development and manufacturing.

In addition, approximately 80% of the sales amount is exported overseas, making the company a top global manufacturer in textile machinery parts.

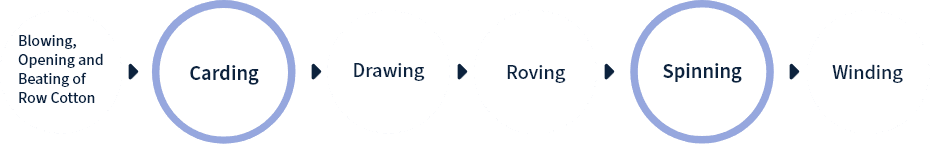

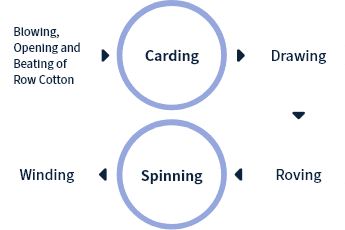

Roles of TEXTILE MACHINERY PRODUCTS

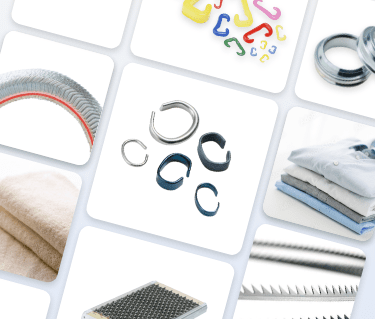

KANAI's textile machinery products "Traveller/Ring" and "Card Clothing/Metallic Wire" are parts mainly used in the process of making "yarn" before making clothes.

In the spinning process, it is used in two important processes that determine the yarn quality.

-

Carding

Products: Card Clothing and Metallic Wire

Card clothing and metallic wires are mounting on the carding machine and used to remove impurities from the raw cotton and align the tangled fibers in a specific direction.

-

Spinning

Products: Traveller and Ring

They are used as parts for spinning machines and twisting machines in the spinning process of cotton spinning and in the twisting process of glass fiber, etc, where they add twist to the yarn to give it strength.

Product Introduction

-

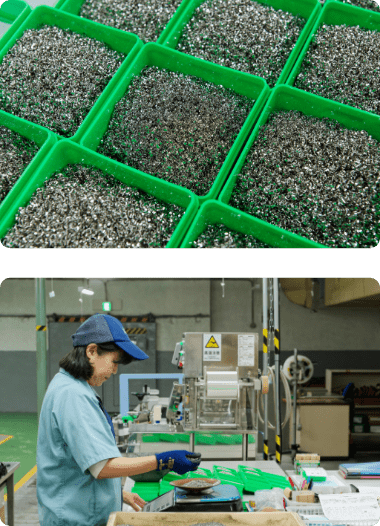

Traveller

It influences the spinning and twisting processes.

It is used in combination with ring as the parts of the spinning/twisting machine in the spinning process of spun yarn and twisting process of glass fiber.etc

Traveller run on a ring with an inner diameter of about 34 to 60 mm for spinning, and about 100 to 216 mm for twisting. In the latest spinning machines, Traveller must be able to withstand high wear and have stable running performance under the running conditions at a speed of nearly 200 km/h.

We particularly care about the materials we use, and our group company TOKUSEN KOGYO manufactures the materials specifically for Traveller. In addition, stable running performance and a long life have been achieved even under high-speed spinning conditions by performing special heat treatment and surface treatment during manufacturing process.

We are capable of manufacturing 3,000 types of Traveller, allowing them to perform well with a wide range of fibers under any conditions. -

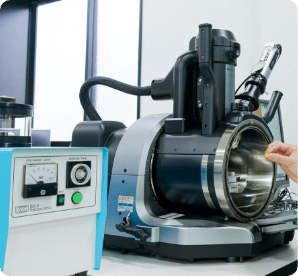

Ring

It improves quality of “yarn” in combination with Traveller.

In the spinning process of cotton spinning and the twisting process of glass fiber, etc., it is attached to the spinning/twisting machine and acts as a rail that Traveller run along.

The latest spinning machines are designed to enable the stable running of Traveller that run at a speed of nearly 200 km/h, and it is possible to maintain stable yarn quality for a long period of time by applying a special surface treatment to achieve high abrasion resistance. -

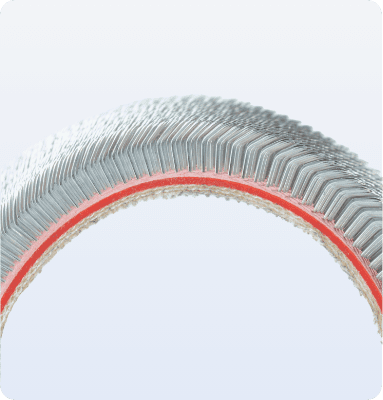

Card Clothing

Infinite Possibilities

Card clothing is used for various applications in a wide range of fields, including not only for wool and cashmere spinning, and for raising fleece and blanket in clothing products, but also for polishing electric wires and pipes, surface treatment of building boards, wig manufacturing process, laser processing machine parts, pet brushes, and the crawlers of small robots.

We manufacture card clothing by combining the technologies of our own company and those of our group companies, that leads us to have numerous variations, allowing you to choose the most suitable one for your application. -

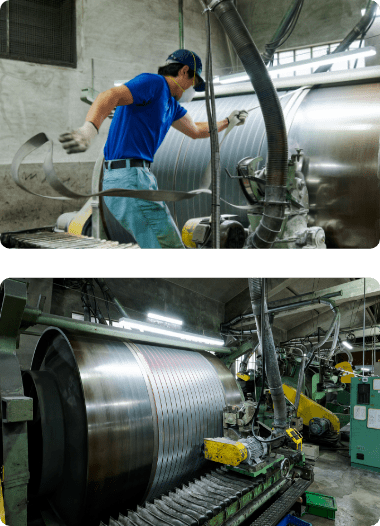

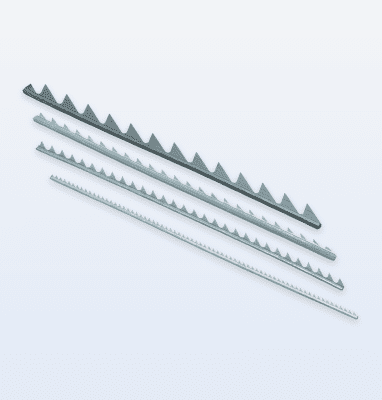

Metallic Wire

It removes debris from raw cotton material and aligns fiber direction.

This Metallic Wire has a sawtooth shape and is used to comb fibers, remove impurities and short fibers, and align fiber direction in the carding process of cotton spinning and non-woven.

In order to give it high hardness, the strength of the sawtooth tips is increased by the special quenching treatment. Depending on the application, surface treatments such as plating and special coatings are applied to them.

We can provide products that meet your needs. In addition to selling products, we also undertake winding work to the carding machine and the manufacture of Wire Mounting Machine.

CONTACT

If you have any inquiries, please feel free to contact us by telephone or email.